Technica Engineering´s test benches and HIL systems are flexible, custom tailored lab benches used in different development and testing projects for Automotive E/E systems.

We offer the following Test Benches and HIL systems:

- Our Component test bench for timesync tests is a bench for testing, if time synchronization (gPTP) within the Ethernet network of a car is working correctly. It contains a Linux-based test suite with different test cases on the component level. Examples for test cases are jitter measurements, latency tests or tests including manipulated gPTP messages.

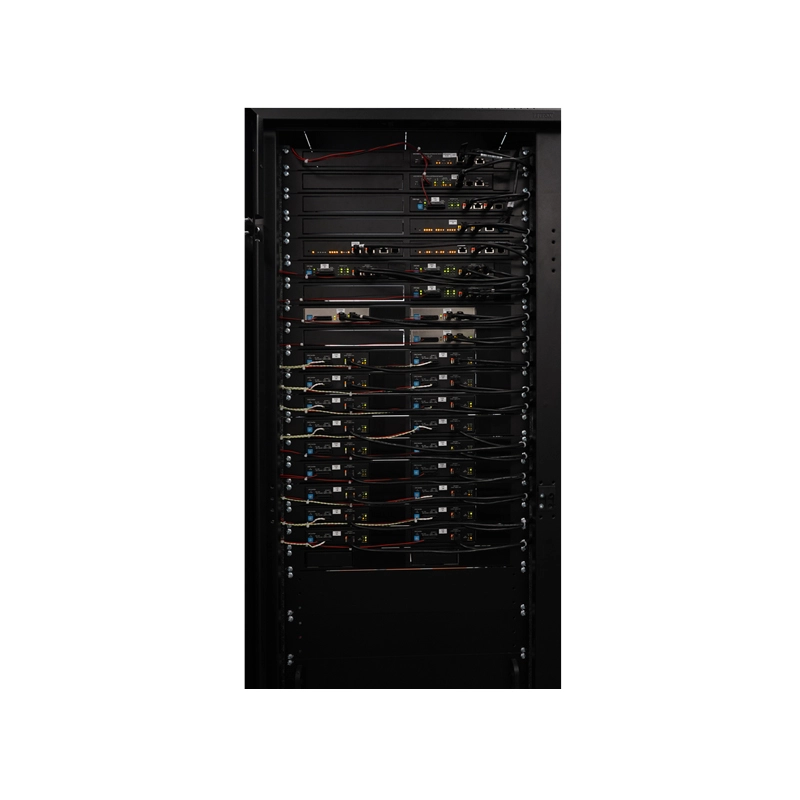

- Our Customized Test Benches are highly scalable test systems using the combination of our dedicated hardware components and software frameworks, like the ANDi (Automotive Network Diagnoser) tool. According to your individual needs, our engineers can design the perfect test system to validate your ECUs. Our test benches provide a large processing capacity for test cases that are deployed by the user. With automated scripts, the system can run test cases simultaneously to achieve high speed test runs.

- The Ethernet Network Test Bench by Technica Engineering is a hardware test bench that is used by our engineers to validate the overall Ethernet communication between ECUs on a system test level. Focusing on different phases of the communication (lifecycle), its main objectives are to control the quality of the protocols implemented in the ECUs and detecting errors in the tracked communication. Further, the validation of the implementation of the OEM message database (FIBEX, ARXML), as well as the testing of the TCP/IP stack are in the focus. The Ethernet Network Tester can be used to test the SOME/IP and SOME/IP-SD protocols, but also for diagnostics tests, UDP-NM tests, switch tests and further test scenarios related to the system testing of a network including Automotive Ethernet.

- Our Body Electronic Test System (BTS) is a 19” test bench that is used in different customer projects. It allows the user to develop and test complex, central ECUs efficiently and with high reliability. With this test bench, our engineers have developed an automated system that was originally designed to ensure that the complex message distribution with window motors, door contact sensors, brake activation and other Body&Comfort ECUs is handled correctly from a central domain controller unit. Our BTS test bench includes twelve channels for the simulation of hardware inputs and outputs, while additionally including Automotive Ethernet, CAN, LIN and FlexRay bus topologies. Up to 448 In- and Output channels can be tested with this flexible test bench.

Fits well with

Switch-Based Products

Product and Test Solutions

Capture Modules

Product and Test Solutions

videos

see it happening